Essential for Modern Technology

As the global shift towards renewable energy and portable electronic devices accelerates, the demand for lithium batteries is experiencing exponential growth. These batteries, which power everything from electric vehicles to personal gadgets, require precision manufacturing within highly controlled environments. Dry cleanrooms are specialized facilities crucial for ensuring the production of high-quality and safe batteries.

The Importance of Dry Cleanrooms

Dry cleanrooms are designed to control particulates, contaminants, and critically, humidity levels. Lithium battery components are particularly sensitive to moisture, which can degrade materials or cause hazardous reactions. By maintaining an ultra-low humidity environment, these cleanrooms prevent chemical instabilities that could lead to reduced battery efficiency, shortened lifespan, and even dangerous safety incidents like explosions. This precise humidity control is vital for maintaining the integrity and performance of the batteries throughout the production process.

Vital Importance of Controlled Environments

The manufacturing process for lithium batteries involves materials that react unfavorably to moisture. Humidity can harm batteries, making them perform poorly and not last as long. In extreme cases, it can even cause explosions.

Dry cleanrooms address these challenges by maintaining humidity levels typically below 1% relative humidity. This meticulous control is especially crucial during the critical phases of electrolyte insertion and cell assembly, where the slightest contamination could have profound repercussions.

Advanced Humidity and Temperature Control

To achieve these stringent conditions, battery dry cleanrooms employ state-of-the-art dehumidification systems, often featuring dual rotor desiccant dehumidifiers. These systems are more energy-efficient than older models and capable of reaching and maintaining dew points as low as minus 80 degrees Celsius. Temperature control is equally vital, as the chemical processes in battery production are highly temperature-sensitive. Maintaining precise temperature conditions ensures the stability and longevity of the battery components.

Air Quality Management

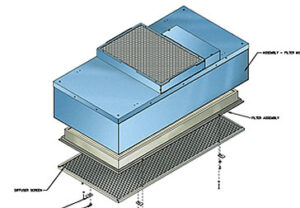

HEPA filters are used in dry cleanrooms to manage air quality meticulously. These filters remove particulate contaminants from the air, which is crucial for maintaining the cleanroom’s integrity and preventing external contaminants from affecting the sensitive battery manufacturing processes. The systems are designed to handle high volumes of air changes per hour, continuously refreshing the environment to guard against potential contamination.

Customizable Modular Solutions

The modular design of dry cleanrooms provides scalability and flexibility in configuration. This adaptability allows the cleanroom to be tailored to specific production needs, whether scaling up for mass production or adjusting layouts for R&D purposes.

It is important to be able to change and grow facilities in the fast-changing technology industry. Adapting quickly to new methods and production sizes is often necessary in this industry. Being able to make necessary changes is crucial for staying competitive. The ability to adapt facilities is important for keeping up with the fast pace of technological advancements.

Energy Efficiency and Operational Sustainability

In an era focused on operational costs and environmental impact, the energy efficiency of dry cleanrooms is a significant concern. These facilities incorporate sophisticated systems designed to minimize energy consumption while maintaining strict environmental controls. Features like energy recovery ventilators and sustainable design practices help reduce the carbon footprint of the manufacturing processes, aligning with global sustainability goals.

Ensuring Safety and Compliance

Safety in the manufacturing of lithium batteries is paramount due to the highly reactive nature of the materials involved. Dry cleanrooms are equipped with numerous safety features, including explosion-proof fixtures and static control systems, to prevent incidents that could endanger workers or compromise the manufacturing process. Compliance with international safety and quality standards is a top priority, ensuring that these manufacturing facilities meet rigorous global benchmarks.

Conclusion on Manufacturing Lithium Batteries

Dry cleanrooms are indispensable in the lithium battery manufacturing industry, providing the essential conditions needed for the safe, efficient, and effective production of these batteries. By controlling humidity, temperature, and air quality, and offering flexible and scalable designs, these cleanrooms play a crucial role in ensuring the production of reliable and high-quality batteries.

As the demand for lithium batteries continues to surge, the technology and processes behind their production will remain critical, establishing dry cleanrooms as a cornerstone of the industry. These specialized environments not only support the technological advancement of battery production but also contribute significantly to the broader transition towards sustainable and renewable energy sources.

Â